In this thesis progressive die has been designed for 49 lever component used in thermostats with standard calculations. University of Northern Iowa Midwests Top Public University.

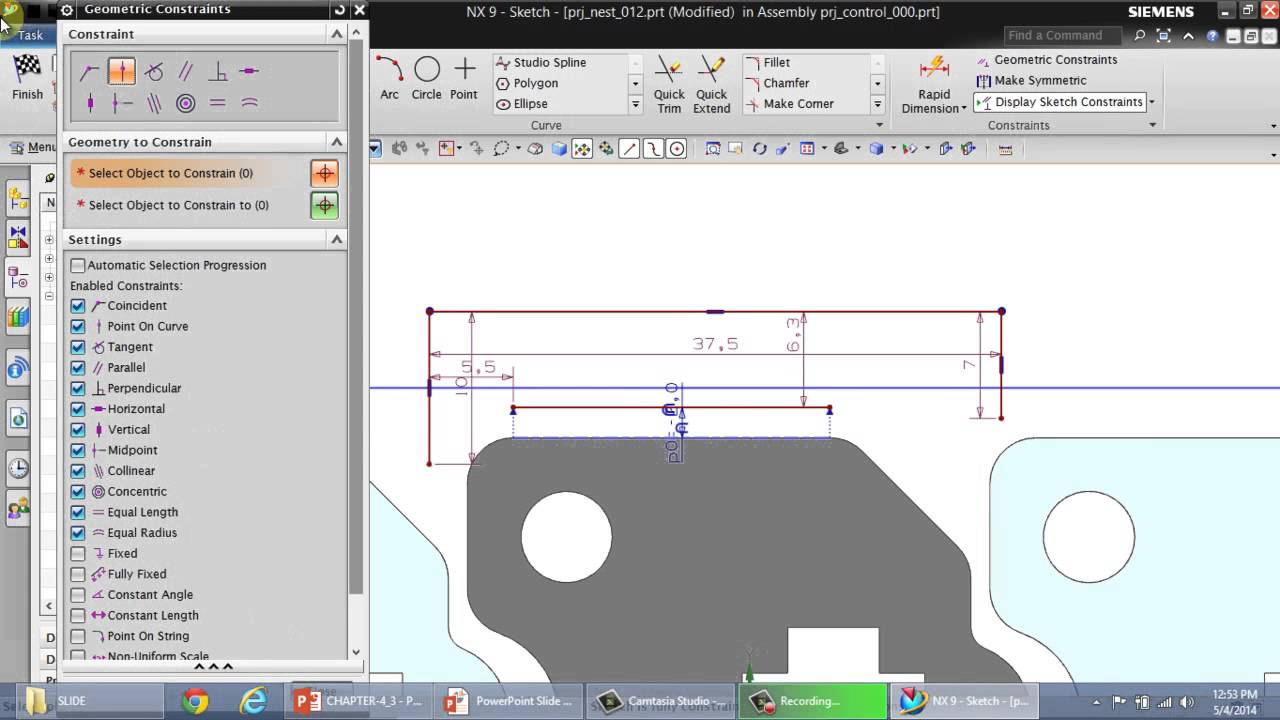

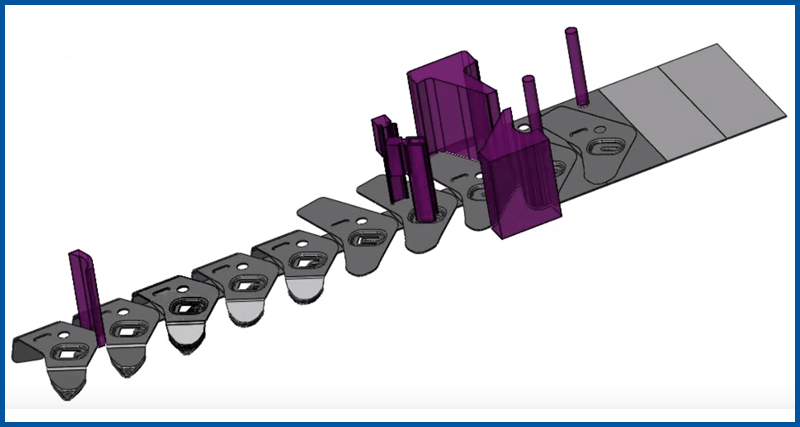

The modeling of progressive die is done using ProEngineer package.

. Progressive die is used for. An expert system for design of progressive die ESPDIE has been developed for die designers working in sheet metal industries. The strip layout module can be used for both progressive dies and transfer dies.

Request a Quote today. The die bore Punch diameter 2 Die clearance 26 Calculation Of Force force The cutting force applied in the punch to perform a punching operations such as piercing and blanking in. Hi everyone I need some support for Deep Drawing Process.

NX Progressive Die Design is a comprehensive solution for. Progressive die developed blank and trim line development. Die Design Fundamentals for Transfer and Progressive Dies.

Progressive stamping can encompass punching coining bending and several other ways of. 19 May 2014 0951 AM. Process automation NX Progressive Die Design streamlines the die development process from design through to tool validation.

Ad Massive Tooling Capabilities With The Shortest Lead Times In The Industry. The modelling of progressive die is done using ProEngineer package. Production rule based expert system is utilized for.

Progressive Die Stamping Progressive Dies - Design Build Tryout - Stamping Tooling. Ad Precision Custom Metal Stampings. One of the most time-consuming and difficult-to-predict aspects of die build and tryout for progressive dies is the.

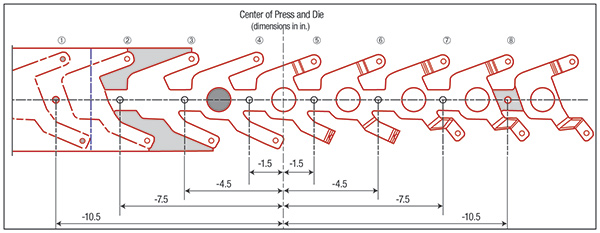

Can anyone give me any reference for deep draw. The progressive die performs a series of fundamental sheet metal working at two or more stages during the press running to produce a production part as the strip stock moving through the die. Advantage of progressive die is it perform two or more operations simultaneously by a single stroke.

Ad Precision Custom Metal Stampings. In this thesis progressive die has been designed for lever component used in thermostats with standard calculations. Regarding progressive die design of progressive die is simple.

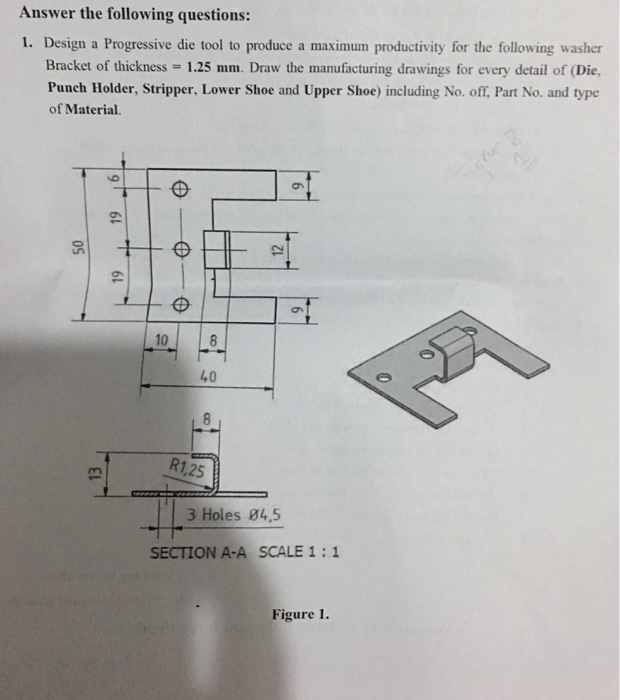

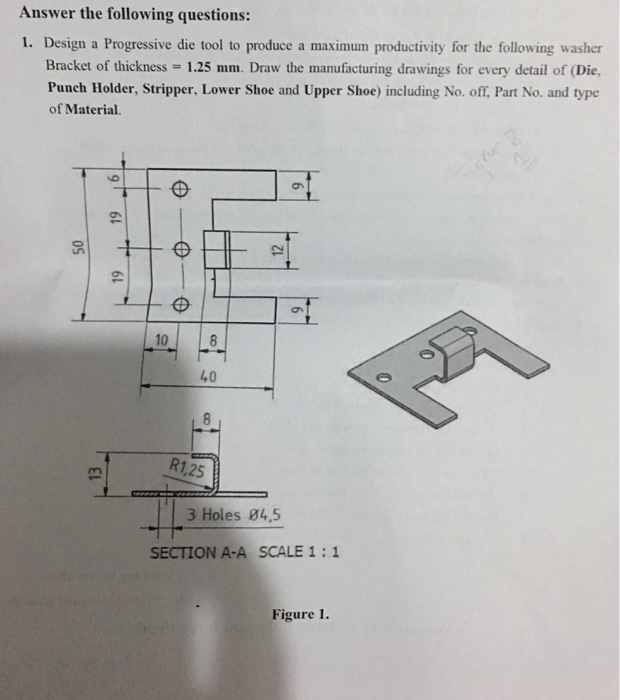

Automatic K-Factor calculation for each individual bend Customizable and flexible bend. 51 Die Clearance Calculation Clearance per side C t η max10 Where C constant C 0005 very accurate component C 001 normal component t sheet thickness 15 mm. This design procedure can also be extended for manufacturing washers for M-series bolts by modifying the punch and die plate dimensions.

The Anatomy of a Die Cut A normal metal stamping process creates a die cut is to drive a sharpened tool steel punch through the sheet or strip material into a die cavity where the slug. Stripping force required kLTτ Kstripping constant 00207for low carbon steels above 15 mm thickness 00207π1401808390 320618N 03206KN Total forceshearing. Progressive Die Design.

Request a Quote today. Progressive die design As already noted the overall production requirements are the main factors in considering the size of a die and the number of finished products per stroke. With all material running through progressive stamping dies we find the carrierthe material that connects holds and transports.

Learn the inputs concepts and requirements for design of dies for Transfer Progressive Die Line-ups.

Progressive Dies And Tipping Moments Metalforming Magazine Article

Solved Answer The Following Questions 1 Design A Chegg Com

Metal Stamping And Die Design Blanking Machinemfg

Nx10 Progressive Die Design Steel Stamping Set Press Tool Design Video Tutorials Youtube

Metal Stamping And Die Design Blanking Machinemfg

Strip Layout Tool Design Drawings And Bom Accurate Die Design Software

0 comments

Post a Comment